Unlocking Root Causes: The Ishikawa Diagram Explained

Ever feel like you're treating the symptoms of a problem, not the actual cause? It's a common frustration. That's where the Ishikawa Diagram, often called a fishbone diagram or cause-and-effect diagram, comes in. This simple yet powerful visual tool helps you drill down to the root cause of any problem, enabling you to implement effective solutions.

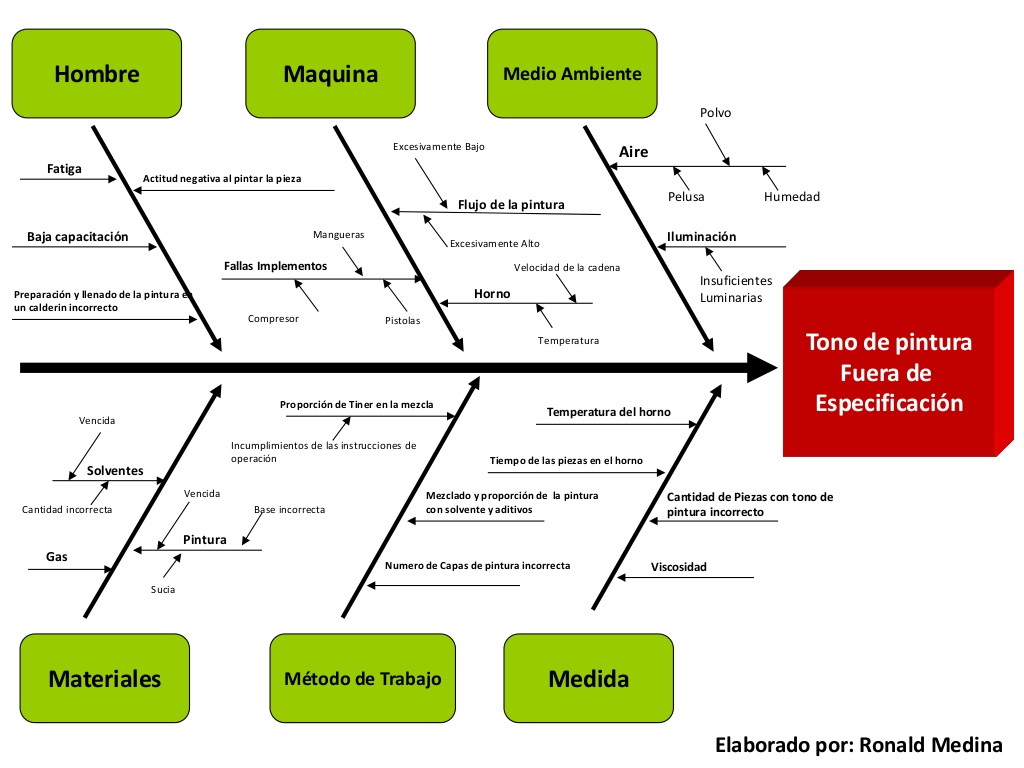

Imagine a fish skeleton. The "head" represents the problem you're trying to solve, and the "bones" branching out represent the potential causes. These causes are typically categorized into major areas like people, processes, materials, equipment, environment, and measurement. By brainstorming and visually mapping these potential contributing factors, the Ishikawa Diagram helps teams gain a shared understanding of the complex interplay of elements that lead to a particular issue.

Developed by Kaoru Ishikawa, a Japanese organizational theorist, in the 1960s, the Ishikawa Diagram emerged as a key component of quality management practices. Originally used in manufacturing, its versatility has led to its widespread adoption across various industries, from healthcare to software development. Its enduring popularity lies in its ability to facilitate collaborative problem-solving and foster a deeper understanding of complex systems.

The core principle behind the Ishikawa Diagram is that problems don't exist in isolation. They are often the result of a confluence of factors. Simply addressing surface-level symptoms without identifying the underlying root causes leads to recurring issues and wasted resources. The diagram provides a structured approach to dissecting a problem and revealing its underlying drivers.

The power of the Ishikawa Diagram lies in its simplicity and visual nature. It's a collaborative tool that encourages team participation and brainstorming. By bringing together diverse perspectives, the diagram helps uncover hidden factors that might have otherwise been overlooked. This collaborative approach fosters a shared understanding of the problem and builds consensus around potential solutions.

One key benefit is its ability to identify root causes. By visually mapping potential causes, the diagram helps teams move beyond surface-level symptoms and pinpoint the underlying drivers of a problem. For example, a delay in project delivery might be caused by unclear requirements, inadequate resources, or communication breakdowns, not just a single missed deadline.

Another benefit is improved communication. The visual nature of the diagram facilitates clear communication and shared understanding among team members. Everyone can see the potential causes and their relationship to the problem, fostering alignment and collaboration.

Finally, the Ishikawa Diagram promotes proactive problem-solving. By identifying potential causes, teams can develop preventive measures to avoid similar issues in the future. This proactive approach helps organizations minimize disruptions and improve overall efficiency.

To create an Ishikawa Diagram, start by clearly defining the problem. Then, identify the main categories of potential causes. Common categories include people, methods, machines, materials, measurement, and environment. Brainstorm potential causes within each category, adding them as branches to the diagram. Once the diagram is complete, the team can analyze the potential causes, prioritize them based on their likely impact, and develop targeted solutions.

Advantages and Disadvantages of Ishikawa Diagrams

| Advantages | Disadvantages |

|---|---|

| Visual and easy to understand | Can become complex for multifaceted problems |

| Facilitates collaboration and brainstorming | May not identify all possible causes |

| Identifies root causes | Requires active participation from team members |

Best Practices:

1. Clearly define the problem: Ensure everyone understands the problem being addressed.

2. Encourage participation: Involve diverse perspectives to gain a comprehensive understanding.

3. Use specific language: Avoid vague or generic terms.

4. Prioritize causes: Focus on the most likely contributors to the problem.

5. Validate assumptions: Test and verify the identified root causes.

Example: A customer service team is experiencing a high volume of complaints. An Ishikawa Diagram could be used to explore potential causes, categorizing them into areas like staff training, communication protocols, website functionality, and product quality.

FAQs

1. What is an Ishikawa Diagram? - A visual tool for identifying the root causes of a problem.

2. What are the benefits of using this diagram? - Improves communication, identifies root causes, promotes proactive problem-solving.

3. Who created the Ishikawa Diagram? - Kaoru Ishikawa.

4. What are the main categories used in the diagram? - People, Methods, Machines, Materials, Measurement, Environment.

5. How can I create an Ishikawa Diagram? - Define the problem, identify categories, brainstorm causes, and add them to the diagram.

6. What are some common mistakes to avoid? - Not clearly defining the problem, lacking team participation, using vague language.

7. Can Ishikawa Diagrams be used in any industry? - Yes, they can be applied to various fields.

8. What other names are used for the Ishikawa Diagram? - Fishbone Diagram and Cause-and-Effect Diagram.

Tips and Tricks:

Use sticky notes for brainstorming, making it easy to move ideas around. Start with broad categories and then drill down into more specific sub-causes. Don't be afraid to challenge assumptions and explore unconventional ideas. Document the process and the rationale behind identified root causes.

In conclusion, the Ishikawa Diagram is a valuable tool for anyone looking to solve problems effectively. Its simplicity, visual nature, and collaborative approach make it a powerful asset for individuals and teams across various industries. By facilitating the identification of root causes, it empowers organizations to implement targeted solutions, prevent recurring issues, and improve overall performance. Embrace the Ishikawa Diagram as a key component of your problem-solving toolkit, and unlock the power of root cause analysis to drive continuous improvement and achieve lasting success. Don't just treat the symptoms, address the root cause and create lasting solutions.

Putnam standefer reed funeral home dunlap

Framing the narrative mastering art above your king size bed

Leaky faucet got you down conquer tub shower faucet repair yourself

diagrama de ishikawa que es y para que sirve | Solidarios Con Garzon

O Diagrama De Ishikawa Também é Conhecido Como | Solidarios Con Garzon

Para Que Se Utiliza El Diagrama De Ishikawa | Solidarios Con Garzon

Diagrama De Ishikawa Para Que Sirve | Solidarios Con Garzon

diagrama de ishikawa que es y para que sirve | Solidarios Con Garzon

DIAGRAMA DE ISHIKAWA Blog Lean THiNK PRODUCTIVITY | Solidarios Con Garzon

diagrama de ishikawa que es y para que sirve | Solidarios Con Garzon

Diagrama De Ishikawa Ejemplo | Solidarios Con Garzon

Diagrama De Ishikawa Images | Solidarios Con Garzon

diagrama de ishikawa que es y para que sirve | Solidarios Con Garzon

Diagrama De Ishikawa Medida | Solidarios Con Garzon

Cómo hacer el diagrama de Ishikawa | Solidarios Con Garzon

Diagrama Ishikawa qué es y cómo te ayuda a potenciar tu negocio | Solidarios Con Garzon

Diagrama Ishikawa Para qué sirve | Solidarios Con Garzon

Diagrama De Ishikawa En Word En 2021 Diagrama De Ishikawa Ishikawa | Solidarios Con Garzon