Metric vs. Standard Tools: Unraveling the Measurement Mystery

Ever found yourself staring blankly at a toolbox, wondering about the difference between those cryptic metric and standard markings on your wrenches or sockets? You're not alone. The seemingly simple act of choosing the right tool can become a puzzling dilemma when faced with two distinct measurement systems. This exploration into the world of metric versus standard tools aims to demystify these differences, providing you with the knowledge to confidently tackle any project.

Understanding the variations between metric and standard tools is crucial for anyone working with mechanical components, DIY projects, or even just assembling furniture. Choosing the wrong tool can lead to stripped bolts, damaged equipment, and ultimately, a frustrating experience. This isn't just about numbers; it's about precision, compatibility, and ensuring your project goes smoothly.

The disparity between these two systems stems from their historical origins. The metric system, a decimal-based system, emerged from the French Revolution and is now the internationally recognized standard for measurement. Standard or imperial units, with their roots in ancient Roman and Anglo-Saxon measurements, remain prevalent in the United States. This historical divergence has led to a world where understanding both systems is often essential.

The importance of understanding the metric vs. standard tool distinction is amplified in today's globalized world. International collaborations, supply chains, and product specifications often require a fluency in both systems. This knowledge not only prevents costly errors but also fosters seamless communication and collaboration across borders.

One of the main issues surrounding the use of different measurement systems is the potential for confusion and incompatibility. Imagine trying to tighten a metric bolt with a standard wrench – the mismatch can lead to damage and frustration. Therefore, correctly identifying and utilizing the appropriate tool for the job is paramount.

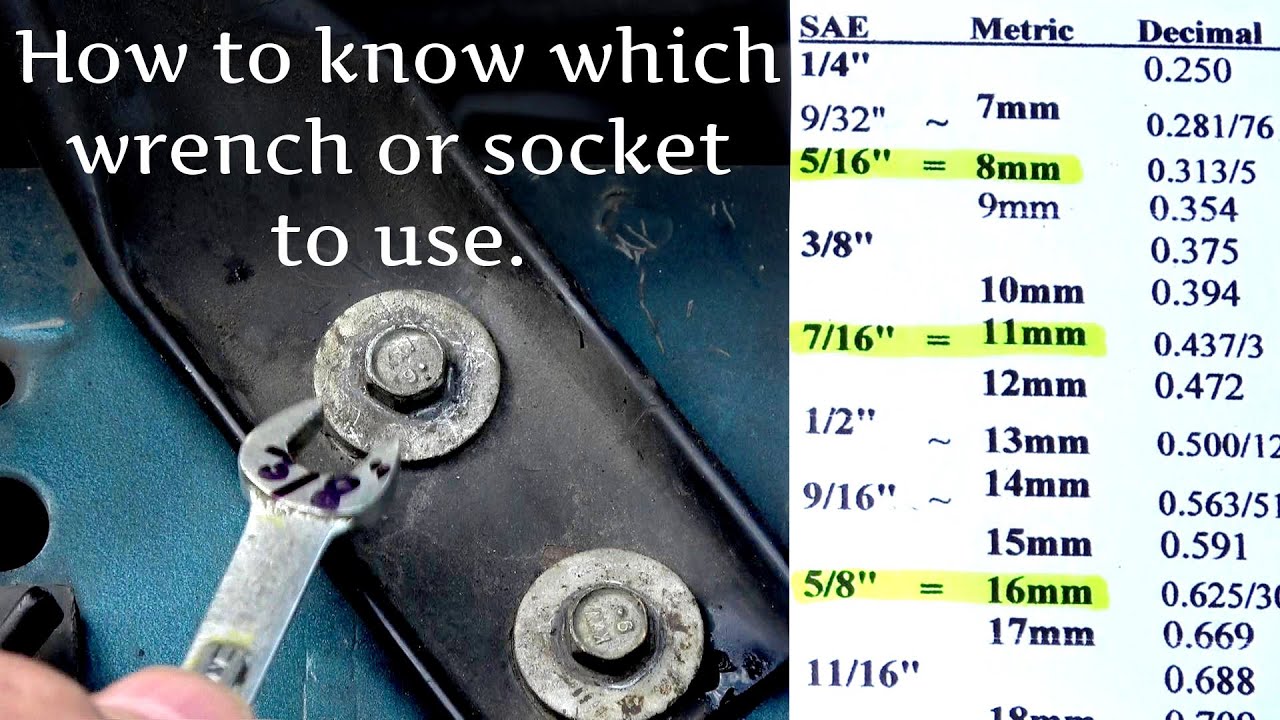

Metric tools are based on millimeters (mm) and centimeters (cm), while standard tools use inches, feet, and fractions thereof. A simple example is a 10mm socket versus a 3/8 inch socket – they appear similar but are not interchangeable. Understanding these basic unit conversions can prevent significant headaches down the line.

Navigating the metric and standard tool world can seem daunting, but a few key strategies can simplify the process. Clearly label toolboxes and storage areas, separating metric and standard tools to avoid mix-ups. Invest in conversion charts or apps for quick reference, and double-check measurements before selecting a tool. These simple steps can save you time and prevent costly mistakes.

Advantages and Disadvantages

| Feature | Metric | Standard |

|---|---|---|

| Ease of Use | Decimal-based, simpler calculations | Fractions can be more complex |

| Global Acceptance | Widely used internationally | Primarily used in the US |

| Availability | Increasingly common worldwide | Readily available in the US |

Frequently Asked Questions:

1. What is the main difference between metric and standard tools? The primary difference lies in the units of measurement they use.

2. Why are there two different systems? Historical reasons and regional preferences account for the continued use of both systems.

3. Can I use metric and standard tools interchangeably? No, using mismatched tools can damage equipment.

4. How do I identify a metric tool? Look for millimeter (mm) or centimeter (cm) markings.

5. How do I identify a standard tool? Look for inch markings, often using fractions.

6. Where can I learn more about metric and standard conversions? Numerous online resources and conversion charts are available.

7. What are some common metric socket sizes? Common sizes include 10mm, 13mm, and 17mm.

8. What are some common standard socket sizes? Common sizes include 1/2 inch, 9/16 inch, and 3/8 inch.

One useful tip is to visually familiarize yourself with the common sizes in both systems. This visual recognition can speed up tool selection and reduce errors.

In conclusion, navigating the world of metric and standard tools requires a clear understanding of their differences, origins, and practical applications. By recognizing the importance of choosing the correct tool for each task, you can prevent damage, improve efficiency, and ultimately enhance your project outcomes. Whether you’re a seasoned professional or a weekend DIY enthusiast, embracing this knowledge empowers you with the precision and confidence to tackle any project. Take the time to learn the distinctions, invest in the right tools, and watch your projects come to life with accuracy and ease. The ability to seamlessly transition between both measurement systems is a valuable skill in today's interconnected world, unlocking opportunities for collaboration, innovation, and successful project completion. So, the next time you reach for a wrench, you'll be equipped to make the right choice, confidently tackling the task at hand.

Unlocking usaa auto loans your credit score guide

Aesthetic laptop wallpapers embrace the cute stitch vibe

Find your dream car billings mt cars for sale by owner

Metric Standard Bolt Sizes Chart | Solidarios Con Garzon

Wrench Conversion Chart for SAE Metric Sizes w Bolt Diameter Guide | Solidarios Con Garzon

Torque Conversion Tables Metric To Imperial | Solidarios Con Garzon

Metric Bolt Grade Is Indicated By | Solidarios Con Garzon

US to Metric Conversions | Solidarios Con Garzon

Printable Metric Conversion Chart | Solidarios Con Garzon

Size Chart For Sockets | Solidarios Con Garzon

We are back at it again with another hex key size comparison We | Solidarios Con Garzon

Standard Size Socket Chart at Paul Byrd blog | Solidarios Con Garzon

difference between metric and standard tools | Solidarios Con Garzon

Printable Socket Size Chart Metric And Standard | Solidarios Con Garzon

difference between metric and standard tools | Solidarios Con Garzon

SAE TO METRIC WRENCH INTERCHANGE | Solidarios Con Garzon