Conquering the Empty Tank: Mastering Your Fuel Gauge and Sender

Ever been stranded with a sputtering engine and a sinking feeling in your stomach? The culprit? A faulty fuel gauge or sender unit. Understanding how these components work and how to diagnose problems is crucial for every driver. This guide will empower you with the knowledge to confidently assess your vehicle's fuel situation and prevent unexpected roadside dramas.

Fuel gauges and senders have become essential components of modern vehicles. Imagine a world without them – drivers constantly dipping sticks into their tanks, guessing at fuel levels, and frequently running out of gas. The development of these simple yet effective devices revolutionized driving, providing convenience and peace of mind.

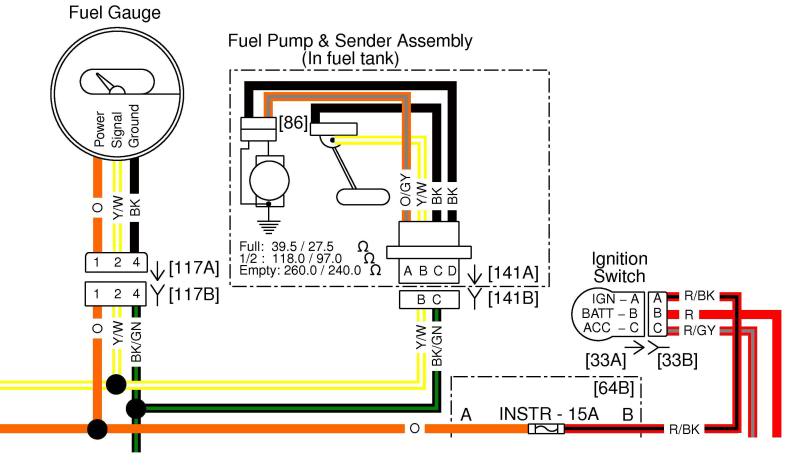

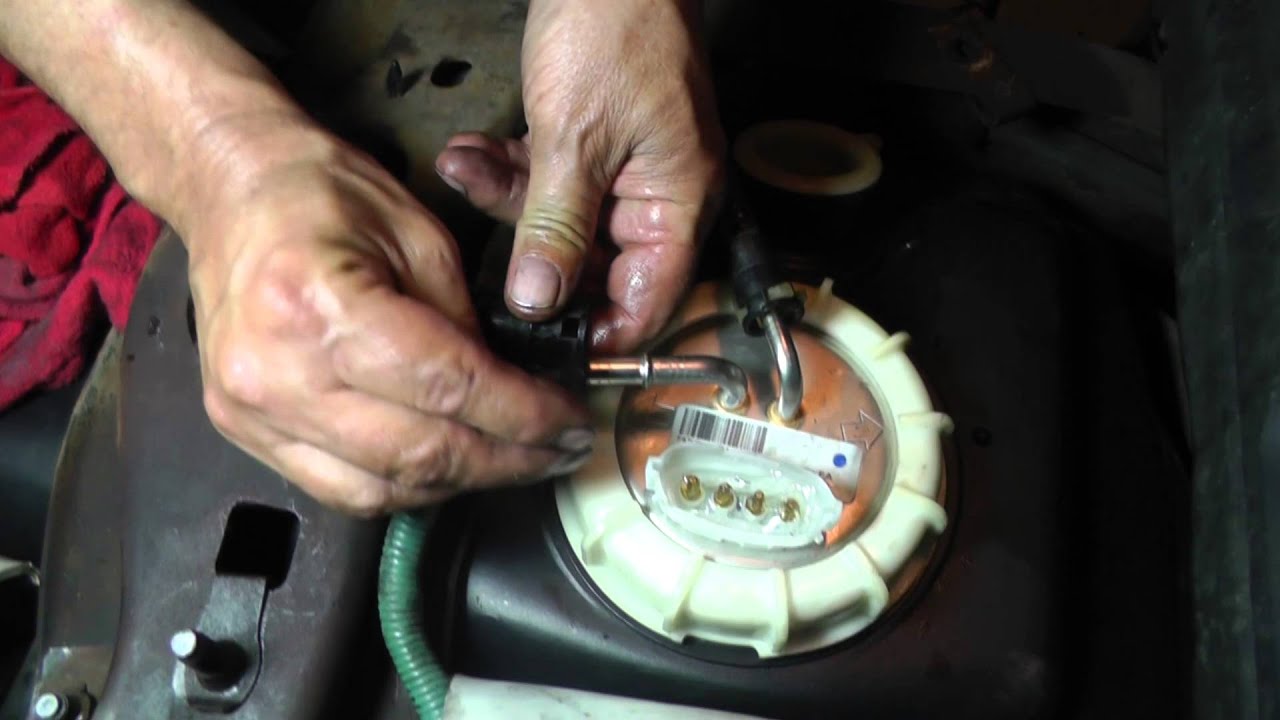

The primary function of the fuel gauge and sender is to accurately reflect the amount of fuel in the tank. The sender, a float-activated variable resistor located inside the fuel tank, measures the fuel level. This information is then transmitted to the fuel gauge on the dashboard, providing a visual representation of the fuel remaining. However, these systems are not without their flaws, and understanding potential issues is critical.

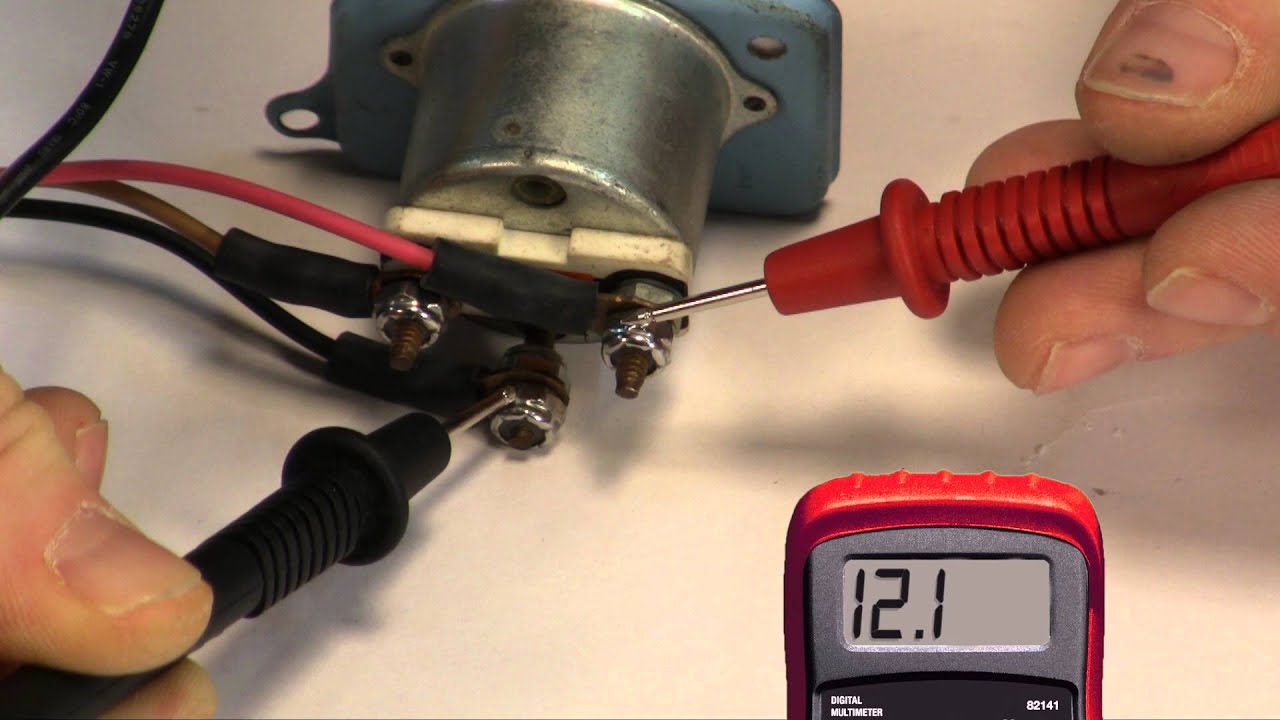

Common problems include a faulty sender unit, a malfunctioning fuel gauge, or wiring issues. Symptoms of a bad fuel gauge or sender might include erratic readings, a gauge that sticks or doesn't move, or a gauge that always reads full or empty. Diagnosing these problems often involves checking the wiring, testing the sender unit's resistance, and inspecting the fuel gauge itself. This guide will delve into the specific steps you can take to troubleshoot these issues.

Mastering the art of checking your fuel system goes beyond simply glancing at the dashboard. It's about understanding the mechanics behind the reading, recognizing the signs of trouble, and taking proactive steps to ensure reliable performance. A proactive approach to fuel system maintenance can save you time, money, and the frustration of an unexpected breakdown.

A simple test involves turning the vehicle's ignition to the "on" position without starting the engine. Observe the fuel gauge. It should move to its usual position, indicating the fuel level. If it doesn't move, it could signal a problem with the gauge, the sender, or the wiring.

One benefit of regularly verifying your fuel system's accuracy is preventing unexpected fuel shortages. By understanding how to assess your fuel gauge and sender, you eliminate the guesswork and gain confidence in your vehicle's range. For example, knowing your gauge is accurate allows you to confidently plan long road trips without the anxiety of running dry.

Another advantage is the early detection of potential problems. Identifying a faulty sender unit before it completely fails can save you from costly repairs down the line. Catching a small issue early often allows for a simpler and less expensive fix.

A third benefit is improved fuel efficiency. A leaking or malfunctioning sender can contribute to fuel evaporation, wasting fuel and money. Addressing these issues promptly helps optimize fuel consumption.

Advantages and Disadvantages of DIY Fuel System Checks

| Advantages | Disadvantages |

|---|---|

| Early problem detection | Potential for misdiagnosis |

| Cost savings on minor repairs | Risk of damaging components |

Best Practices for Checking Your Fuel System:

1. Regular Visual Inspection: Look for any signs of leaks or damage around the fuel tank and fuel lines.

2. Monitor Fuel Gauge Behavior: Pay attention to any unusual fluctuations or inconsistencies in the gauge readings.

3. Perform the Ignition Test: Regularly check the fuel gauge's response when turning the ignition on.

4. Check Wiring Connections: Inspect the wiring connections to the fuel sender unit for any looseness or corrosion.

5. Consult a Professional: If you suspect a serious problem, seek the assistance of a qualified mechanic.

Frequently Asked Questions:

1. What does it mean if my fuel gauge always reads empty? This could indicate a faulty sender unit, a wiring problem, or a malfunctioning gauge.

2. How often should I check my fuel gauge and sender? It's a good practice to monitor your fuel gauge regularly and perform a visual inspection of the fuel system at least once a month.

Conclusion:

Understanding how to check your fuel gauge and sender is more than just a handy skill; it's an essential aspect of responsible vehicle ownership. By familiarizing yourself with the system's components, potential issues, and troubleshooting techniques, you empower yourself to prevent breakdowns, save money, and maintain a reliable and efficient vehicle. Don't let a faulty fuel system leave you stranded – take control of your fuel situation and enjoy the open road with confidence. Taking proactive steps to maintain your fuel system, from regular checks to addressing minor issues promptly, contributes to a safer and more enjoyable driving experience. Remember, a well-maintained vehicle is a happy vehicle.

Decoding vin find your vehicles body code

Dirt late model videos unleash the thrill of high octane racing

Conquering the multiplication table mastering basic math facts

Fuel Sending Unit Wiring | Solidarios Con Garzon

How To Remove Fuel Bowl 73 1997 at Jonathan Little blog | Solidarios Con Garzon

Fuel Pump Wire Gauge | Solidarios Con Garzon

How To Test Fuel Gauge And Sender | Solidarios Con Garzon

How To Check Fuel Gauge And Sender | Solidarios Con Garzon

How To Check Fuel Gauge And Sender | Solidarios Con Garzon

Auto Parts Accessories 38 66 67 68 69 FairlaneComet Stainless 68 | Solidarios Con Garzon

Boat Fuel Sender Wiring Gauge | Solidarios Con Garzon

New Car Fuel Gauge Sender Unit in Hamilton | Solidarios Con Garzon

Fuel Sending Unit Diagram | Solidarios Con Garzon

3 Wire Fuel Sending Unit Wiring Diagram | Solidarios Con Garzon

1993 Ford explorer fuel gauge | Solidarios Con Garzon

Digital Fuel Level Indicator Circuit Diagram | Solidarios Con Garzon

How To Wire An Aftermarket Fuel Gauge | Solidarios Con Garzon

Dodge Challenger Engine Swap Compatibility Chart | Solidarios Con Garzon