Banish Bilgewater: Mastering the Float Switch Connection

A swamped boat can ruin a day on the water faster than a rogue wave. Protecting your vessel from accumulating bilgewater is crucial, and a properly connected automatic bilge pump system is your first line of defense. But how do you ensure your pump kicks into action when needed? The key lies in understanding how to wire a float switch, the unsung hero of bilgewater management.

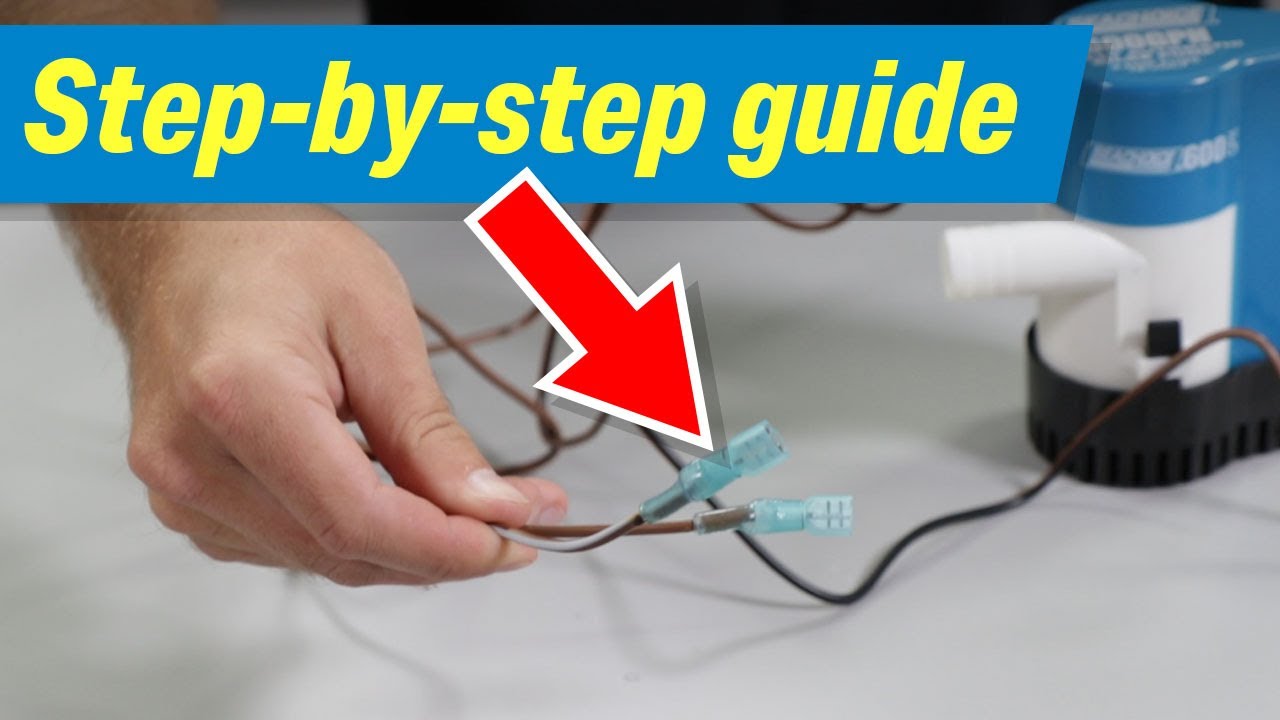

Connecting a float switch might seem intimidating, but with a clear understanding of the process, it's a manageable task for any boat owner. This guide will walk you through the essentials, from basic wiring diagrams to troubleshooting common issues, empowering you to keep your boat dry and safe.

Imagine this: You're out on the lake, enjoying a beautiful day, and suddenly you notice water pooling in your bilge. Without an automatic bilge pump, you'd have to manually bail out the water, disrupting your day and potentially putting your safety at risk. A correctly wired float switch automates this process, activating the pump when water levels rise and deactivating it once the bilge is clear.

The concept of automatically removing bilgewater has been around for decades. Early systems were often unreliable, relying on manual switches or complex mechanical contraptions. The development of the simple and effective float switch revolutionized bilgewater management, providing a reliable and automated solution. The primary challenge in float switch installation lies in ensuring proper wiring for consistent and dependable operation.

A float switch is essentially a buoyant switch that activates and deactivates an electrical circuit based on water level. As water rises, the float rises, closing the circuit and turning on the bilge pump. When the water level drops, the float descends, opening the circuit and turning the pump off. This simple yet ingenious mechanism is the cornerstone of an effective automatic bilge pump system.

Connecting a float switch to a bilge pump offers several significant benefits: Automated Water Removal: Eliminate the need for manual bilge pumping, freeing up your time and ensuring continuous protection. Enhanced Safety: Prevent dangerous bilgewater buildup, which can lead to capsizing or other safety hazards. Peace of Mind: Enjoy worry-free boating, knowing your bilge pump will automatically handle unwanted water.

Advantages and Disadvantages of Automatic Bilge Pump Systems with Float Switches

| Advantages | Disadvantages |

|---|---|

| Automatic operation | Potential switch failure |

| Increased safety | Wiring complexity (for some installations) |

| Peace of mind | Float switch can get stuck or obstructed |

Best Practices for Wiring a Float Switch: 1. Use marine-grade wiring and connectors to resist corrosion. 2. Ensure proper grounding to prevent electrical hazards. 3. Choose a float switch location that allows free movement and avoids obstructions. 4. Double-check all connections for tightness and security. 5. Test the system thoroughly after installation.

Step-by-Step Guide: 1. Disconnect the power supply to the bilge pump. 2. Mount the float switch in a suitable location. 3. Run wires from the float switch to the bilge pump and power source. 4. Connect the wires according to the wiring diagram (consult your pump and switch manuals). 5. Reconnect the power and test the system.

Frequently Asked Questions: 1. What type of wire should I use? (Marine-grade) 2. Where should I mount the float switch? (In a location that allows free movement) 3. How do I test the system? (Manually activate the float switch to ensure the pump turns on.) 4. What if the pump doesn't turn on? (Check the wiring, fuse, and float switch.) 5. Can I use multiple float switches? (Yes, for multiple pumps or redundancy.) 6. What are common float switch problems? (Sticking, corrosion, faulty wiring.) 7. How do I troubleshoot a faulty float switch? (Inspect for damage, check wiring, test with a multimeter.) 8. What safety precautions should I take? (Disconnect power before working on the system.)

Tips and Tricks: Consider installing a manual override switch for added control. Periodically inspect and clean the float switch to ensure proper operation. Use a wire diagram specific to your pump and switch model.

Effectively managing bilgewater is paramount to safe and enjoyable boating. Understanding how to wire a float switch to your bilge pump empowers you to take control of this crucial aspect of boat maintenance. By following the guidelines and best practices outlined in this guide, you can confidently install and maintain your automatic bilge pump system, ensuring a dry bilge and worry-free time on the water. Don't let bilgewater ruin your next boating adventure – take the time to master the float switch connection and enjoy the peace of mind it provides. Invest in quality components, test your system regularly, and consult with a marine electrician if needed. Your boat and your peace of mind will thank you.

Crafting a digital first impression discord server icon size recommendations

Shih fa rubber industries a deep dive into rubber manufacturing

Unlocking the secrets of ohio vegetable gardening the ultimate planting guide

Wiring Diagram For Float Switch | Solidarios Con Garzon

How To Wire Float Switch To Pump | Solidarios Con Garzon

Bilge Pump Float Switch Wiring | Solidarios Con Garzon

How To Wire A Bilge Pump Switch | Solidarios Con Garzon

Bilge Pump Wiring With Float Switch | Solidarios Con Garzon

Bilge Pump Float Switch Wiring | Solidarios Con Garzon

Attwood Float Switch Wiring Diagram | Solidarios Con Garzon

Bilge Pump Float Switch Wiring | Solidarios Con Garzon

How To Wire A Float Switch For A Bilge Pump at James Belcher blog | Solidarios Con Garzon

Water Float Switch Wiring Diagram | Solidarios Con Garzon

How To Install A Bilge Pump And Float Switch at Josephine Neal blog | Solidarios Con Garzon

Attwood Float Switch Wiring Diagram | Solidarios Con Garzon

Automatic Bilge Pump Switch Wiring | Solidarios Con Garzon

Bilge Pump Wiring With Float Switch | Solidarios Con Garzon

Bilge Pump Switch Wiring | Solidarios Con Garzon